Medical-Grade HEPA Air Outlet | 500 CMH | EN 1822 & EU GMP

Product Details:

| Place of Origin: | Guangdong, China |

| Brand Name: | MRJH |

| Certification: | ISO 14644、FDA、EU GMP |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Price: | Contact Us |

| Delivery Time: | 7-15 working days |

|

Detail Information |

|||

| Custom Made: | Support | Official Website: | Www.ffu-cleanroom.com |

|---|---|---|---|

Product Description

Medical-Grade HEPA Air Outlet | 500 CMH | EN 1822 & EU GMP

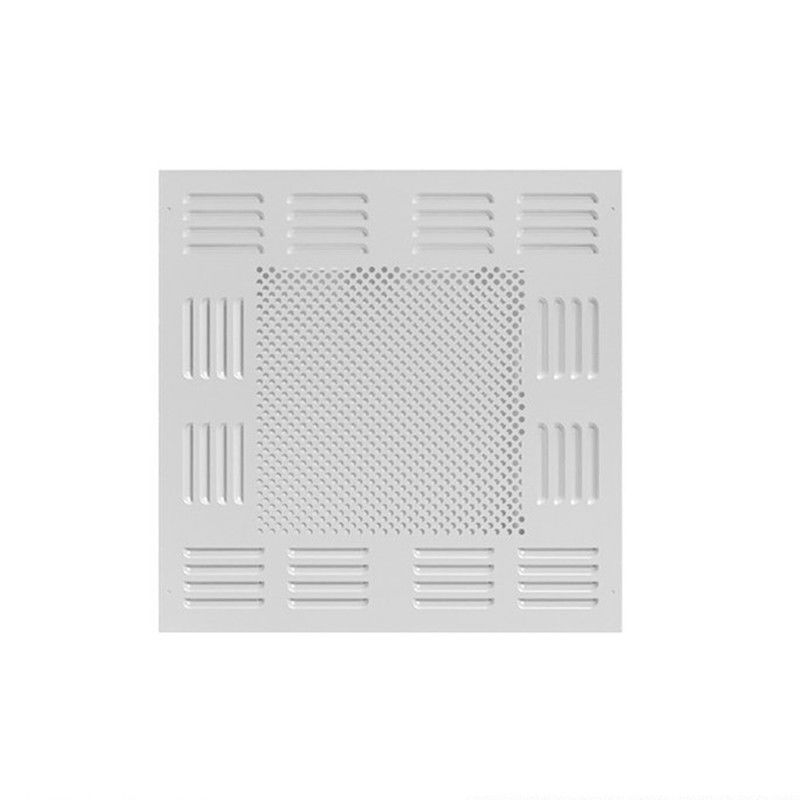

The High-Efficiency Air Supply Outlet is a modular HVAC solution engineered to deliver ISO-certified air quality in industrial and controlled environments. Designed for high-capacity cleanrooms, manufacturing facilities, and critical healthcare spaces, it combines H13 HEPA filtration with precision airflow management. Featuring painted cold-rolled steel construction and a hybrid diffuser system, it ensures compliance with ISO 14644-1 and EN 1822 standards for particulate control.

|

Parameter Name |

Value |

|

Main Body Material |

Painted cold-rolled steel |

|

Diffuser Plate Material |

Painted cold-rolled steel |

|

Air Inlet |

320×200 mm |

|

H13 HEPA Filter |

484×484×90 mm |

|

Body Dimensions |

534×534×460 mm |

|

Ceiling Opening |

539×539 mm |

|

Diffuser Design |

5mm full holes + louver holes |

Key Features

High-Capacity H13 Filtration:

484×484×90 mm filter area ensures extended service life and consistent 99.95% particle retention at 0.3μm.

Industrial Durability:

Powder-coated steel construction resists chemical exposure, humidity, and frequent sanitization.

Adaptive Airflow Management:

Adjustable louvers and 5mm full holes enable ±10% airflow velocity control for ISO Class 5-8 compliance.

Space-Optimized Design:

Compact 534×534×460 mm body maximizes plenum space efficiency in high-bay facilities.

Low-Maintenance Operation:

Tool-free filter access panel reduces downtime during replacements.

Application Scenarios

Pharmaceutical production: High-volume air supply for vial filling lines or lyophilization suites.

Semiconductor fabrication: Particle-controlled environments for wafer processing and cleanroom assembly.

Hospital isolation units: Sterile airflow delivery in ICUs or operating theaters.

Biotech R&D labs: Contamination-free air supply for bioreactors or biosafety cabinets.

Food packaging facilities: Hygienic airflow in high-throughput packaging zones.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

FAQ 1: How does the H13 HEPA filter maintain 99.95% efficiency at 1000 CMH in high-demand industrial environments?

Answer: The EN 1822-tested H13 filter uses reinforced V-shaped pleats and a rigid aluminum frame to handle 1000 CMH without bypass. Aerodynamic sealing ensures 99.95% retention of 0.3μm particles, critical for semiconductor fabs or vaccine production lines.

FAQ 2: Can the 534x534x260mm unit adapt to non-standard ceiling openings in older facilities?

Answer: Yes. Adjustable mounting brackets accommodate ±15mm variances, while the 539x539mm ceiling opening requirement aligns with modular cleanroom grids. Galvanized brackets support retrofits in aging pharmaceutical plants or labs.

FAQ 3: Is the cold plate painted finish resistant to abrasive cleaning in harsh environments?

Answer: The electrostatic epoxy coating withstands frequent scrubbing, bleach, and solvents. Passivated fasteners and sealed joints prevent corrosion in food processing or chemical-exposed facilities.