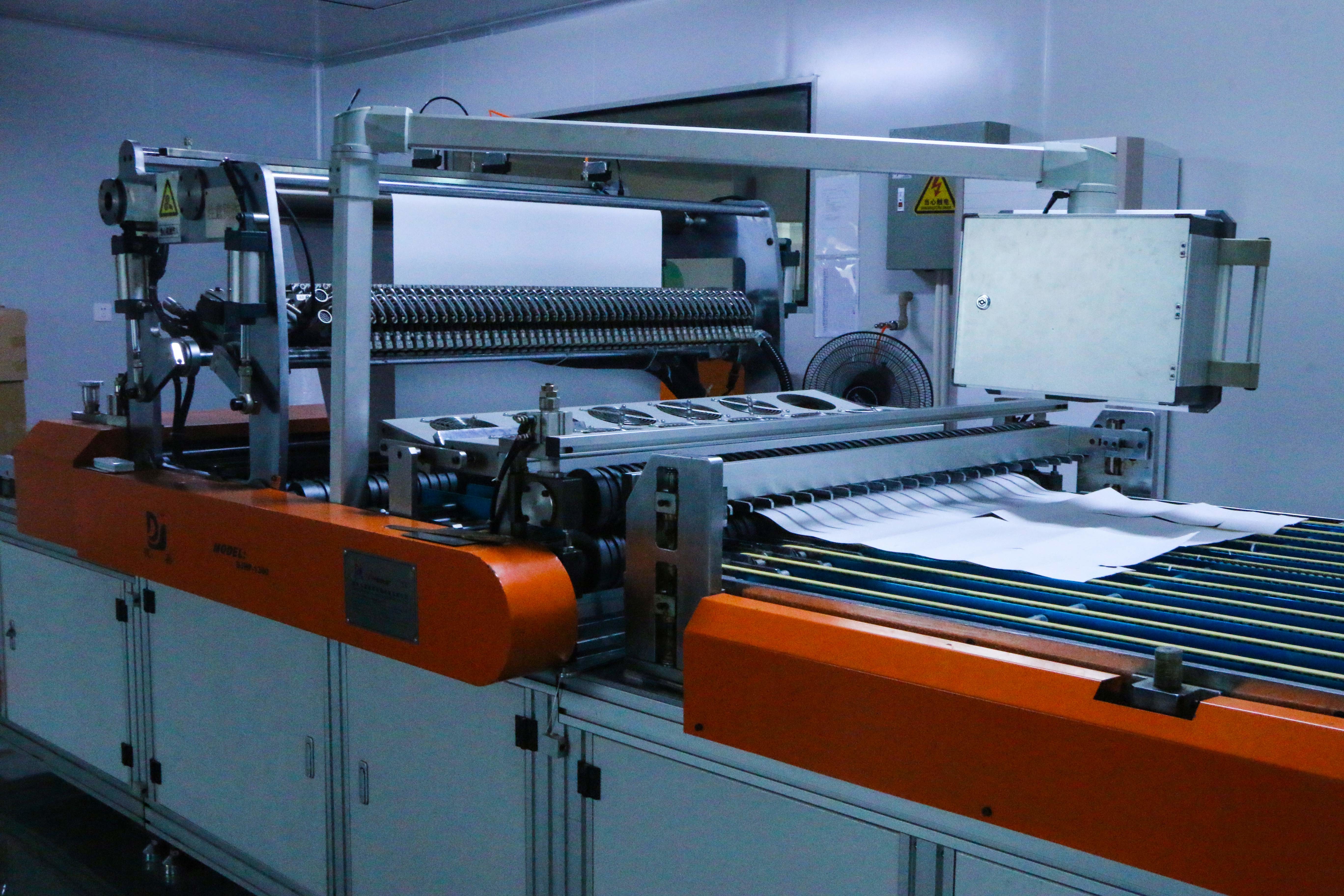

Shenzhen Meiri Purification Technology Co., Ltd. is located in the high-tech city of Shenzhen, China. It has a self built factory area of about 30000 square meters and multiple production lines. In addition, the company has set up specialized purification equipment production workshops, filter production workshops, and pharmaceutical equipment production workshops. There are 2 advanced imported AMADA CNC punching machines, 5 CNC bending machines and 5 shearing machines each, several common punching and folding machines, 2 high-power laser machines for tube and plate integration, and various forming molds.

Shenzhen Meiri Purification Technology Co., Ltd. Core advantages

1. Deep customization capability

Supports customization of non-standard sizes (such as ultra-wide air shower rooms, multi-layer clean rooms), materials (304/316L stainless steel, anti-static coating) and functions (intelligent joint control, energy-saving mode) to meet the needs of GMP, ISO 14644 and other scenarios.

2. Agile delivery system

Self-built 30,000 square meters of digital factory, full-link control of raw materials-production-testing, order response ≤ 24 hours, standard product delivery cycle 15 days, customized projects completed in 30 days at the fastest.

Technical guarantee

Modular design: FFU fan unit, cargo shower room conveyor belt and other components can be quickly disassembled and adapted to reduce customer upgrade and transformation costs.

Cross-industry experience: Serving more than 5,000 customers, covering the fields of medicine, semiconductors, food, etc., and accumulating 800+ non-standard project success cases.

Drawing confidentiality agreement: Strictly follow the NDA terms to ensure the security of customer intellectual property rights and customized solutions.

Certification and quality control

International compliance: ISO 9001 quality management system certification, biological safety cabinets comply with EN 12469 standards, and clean equipment is compatible with FDA audit requirements.

Full process testing: 100% completion of air tightness, wind speed uniformity and filter efficiency testing before leaving the factory, and provide third-party certification reports.

From conceptual design to mass production, we provide one-to-one technical docking and lifelong after-sales support to help customers create cost-effective and highly adaptable clean equipment solutions.

Since its establishment in 2012, Shenzhen Meiri Purification Technology Co., Ltd. has been committed to providing high-end clean room equipment solutions for the global biomedicine, electronic semiconductor, medical equipment and laboratory fields. As a national high-tech enterprise, we are deeply engaged in the research and development and manufacturing of core products such as FFU (fan filter unit), air shower room, cargo shower room, clean room, biological safety cabinet, etc. With 40+ technical patents, an average annual R&D investment of 15% and ISO 9001/ISO 14644 dual certification system, we have established the industry's technical benchmark status.