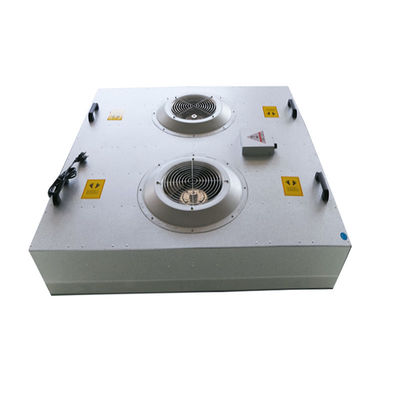

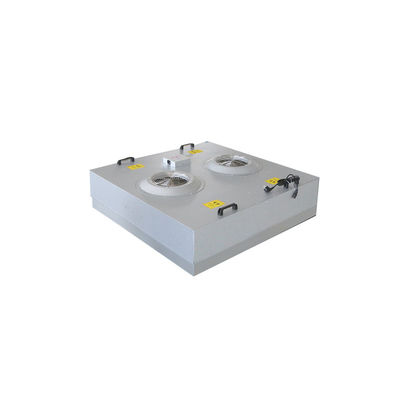

AC Dual-Fan FFU Redundant Airflow System | Pharmaceutical Grade HEPA Filtration | 24/7 Critical Environment Operation

Product Details:

| Place of Origin: | Guangdong, China |

| Brand Name: | MRJH |

| Certification: | ISO,CE,GMP,FDA,UL,ATEX,RoHS |

| Model Number: | AC Dual Fan FFU 1175X1175X215 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Price: | Contact Us |

| Delivery Time: | 7-15 working days |

|

Detail Information |

|||

| Custom Made: | Support | Official Website: | Www.ffu-cleanroom.com |

|---|---|---|---|

| Certification: | ISO,CE,UL,RoHS | ||

Product Description

![]()

AC Dual-Fan FFU Redundant Airflow System | Pharmaceutical Grade HEPA Filtration | 24/7 Critical Environment Operation

The AC Dual-Fan FFU 1175X1175X215 is a fail-safe air filtration solution designed for mission-critical environments requiring uninterrupted operation, such as sterile pharmaceutical production, vaccine fill-finish lines, and high-risk biocontainment labs. With dual EC motors and synchronized airflow control, this unit ensures zero downtime even during fan failure, maintaining ISO Class 3-5 compliance for particulate-sensitive processes.

|

Parameter Name |

Value |

|

Material |

Galvanized aluminum (10 alarms + RS485 protocol) |

|

Impeller System |

MRJH motor + metal impeller |

|

Filtration |

Aluminum frame HEPA filter (1170×1170×69), Efficiency: 99.99% @0.3μm (H13) |

|

Air Speed |

0.45–0.75 m/s ±5% (three-speed adjustment) |

|

Noise Level |

48–58 dB ±5 dB (static test 1.5m below filter) |

|

Power Supply |

220V/50Hz, Rated Power: 300W–380W ±5W |

|

Vibration |

≤5μm peak |

|

size |

1175X1175X215(mm) |

|

Certifications |

ISO 14644-1,ISO 9001,CE |

| Parameter/Feature | Our Product | Market Average | Advantages |

|---|---|---|---|

| H13 Filter Pleat Count | 315 pleats | 260 pleats | Larger filtration area, improving filtration efficiency and dust holding capacity. |

| HEPA Filter | - | - | Increased thickness of filtration media enhances filtration effectiveness and lifespan. |

| Pleat Height | 50 mm | 38 mm | Thicker filtration media improves filtration performance and longevity. |

| Protective Mesh Brand | High-quality 9N brand | Generic brands | Superior support and protection, ensuring structural stability. |

| Frame Thickness | 1.0 mm | 0.7 mm | Stronger frame for enhanced durability and reduced deformation risks. |

| Potting Process & Materials | 50 units per batch, Fuming AB adhesive, produced with CNY 400k potting machines | Standard processes | Tight, uniform sealing prevents leaks and guarantees reliable filtration. |

| Average Airflow Velocity | 0.8 m/s | 0.65 m/s | Higher airflow capacity with lower resistance, boosting system efficiency. |

| Motor | Waterproof | Non-waterproof | Enhanced safety and reliability in diverse environments. |

Key Features

1. Smart Construction: Galvanized aluminum casing integrated with 10 alarms and RS485 protocol for real-time monitoring and control.

2. High-Capacity Fan System: Dual Phoenix MRJH motor with metal impeller delivers large air volume and ultra-low noise.

3. Three-Speed Airflow: Adjustable wind speed (0.45–0.75 m/s ±5%) for flexible cleanroom requirements.

4. H13 Filtration: Non-partition HEPA filter achieves 99.99% efficiency at 0.3μm particles.

5. Optimized Power: 300W–380W rated power ensures stable 220V/50Hz operation.

6. Low Vibration: ≤5μm peak vibration for precision-sensitive environments.

Application Scenarios

Cleanroom air purification in pharmaceutical, electronics, and biotech facilities.

High-volume manufacturing zones requiring ISO-certified H13 filtration.

Facilities demanding advanced monitoring (RS485) and multi-alarm systems.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

FAQ :

1. How does the dual-fan design ensure uninterrupted airflow in critical pharmaceutical environments?

The dual-fan redundancy guarantees continuous operation—if one fan fails, the second automatically compensates to maintain ISO 14644-1 compliance, preventing costly production halts or contamination risks in sterile drug manufacturing.

2. What certifications and filtration standards does this FFU meet for GMP-grade cleanrooms?

Equipped with pharmaceutical-grade H14 HEPA filters (99.995% @0.3µm), it exceeds EU GMP Annex 1 and FDA CFR 210/211 requirements. Each unit is ISO 9001/CE certified, with optional PQ/OQ validation support for audit readiness.

3. How is the system optimized for 24/7 operation in energy-sensitive facilities?

Smart power management: Dual EC motors reduce energy use by 30% vs. traditional AC fans, with <150W power draw per fan.

Predictive maintenance: Built-in vibration sensors and RS485 alerts notify teams of filter clogs or motor issues before failures occur.