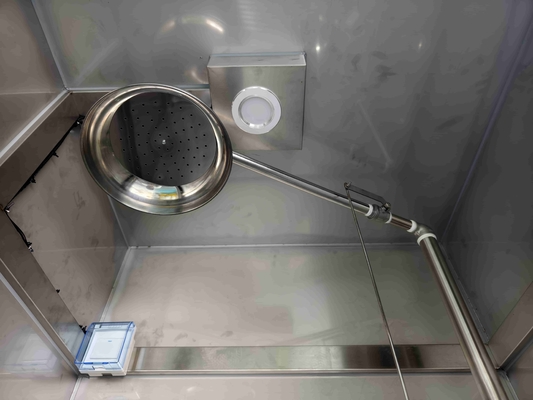

Emergency Safety Shower & Eyewash Room – Stainless Steel Enclosure

Product Details:

| Brand Name: | MRJH |

| Certification: | ANSI,EN,CE,ISO |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Price: | Contact Us |

| Delivery Time: | 7-12 working days |

|

Detail Information |

Product Description

The Emergency Safety Shower and Eyewash Room is designed to provide full-body decontamination and eye protection in case of chemical exposure, toxic splashes, or fire-related accidents. The enclosure is fully welded from SUS304 stainless steel, ensuring excellent durability, corrosion resistance, and long service life.

Equipped with a standard combination eyewash station and a retractable sliding door, the unit prevents wastewater from flowing into the workplace, reducing contamination risks. This makes it highly suitable for industries with strict safety and hygiene standards, such as petrochemical, pharmaceuticals, electronics, food processing, power plants, ports, and firefighting facilities.

![]()

Durable Construction – Fabricated with mirror-polished 304 stainless steel for maximum corrosion resistance and hygiene.

Integrated Eyewash & Shower System – Combines a high-capacity shower head with an eyewash nozzle for rapid response.

Efficient Water Flow –

Eyewash nozzle: 12 L/min

Shower head: 120–180 L/min

Advanced Air Filtration –

Filtration efficiency: Class 100 @ 0.3 μm

Purification rate: 99.99%

Sterilization rate: 99.99%

Power System – Operates under 220V / 50Hz, power consumption below 300W.

Air Supply – Adjustable fresh air volume 1,000–10,000 m³/h for clean and safe use.

Compact Size – 1000 × 1000 × 2400 mm, suitable for limited spaces.

Easy Operation – Electric power control system with user-friendly interface.

Wastewater Management – Sliding door design effectively prevents wastewater leakage.

![]()

| Parameter | Value |

|---|---|

| Material | SUS304 Mirror-Finished Stainless Steel |

| Rated Voltage | 220V |

| Rated Frequency | 50Hz |

| Power Consumption | ≤300W |

| Eyewash Flow | 12 L/min |

| Shower Flow | 120–180 L/min |

| Filtration Efficiency | Class 100 @ 0.3 μm |

| Purification Rate | 99.99% |

| Sterilization Rate | 99.99% |

| Fresh Air Volume | 1,000–10,000 m³/h |

| Overall Dimensions | 1000 × 1000 × 2400 mm |

| Applicable Grade | 300,000-class ~ 100-class cleanrooms |

| Control System | Electric Power Control |

This emergency shower and eyewash room is widely used in:

Electronics Industry – for sensitive cleanroom environments requiring Class 100–300,000 compliance.

Biopharmaceutical Industry – for handling hazardous chemicals and protecting laboratory personnel.

Food Processing Industry – ensuring hygiene and safety compliance.

Petrochemical & Power Plants – emergency protection for operators in high-risk environments.

Firefighting & Port Facilities – rapid response for hazardous material exposure.

Professional-grade 304 stainless steel construction

Integrated shower & eyewash system for maximum safety

Cleanroom-grade purification with 99.99% filtration efficiency

Compact design suitable for high-standard industrial facilities

Reliable emergency protection for personnel safety

Q1: What is an Emergency Safety Shower and Eyewash Room used for?

A1: It is designed to provide immediate decontamination for workers exposed to hazardous chemicals, toxic splashes, or fire-related accidents. The unit combines a full-body shower and an eyewash station within a stainless steel enclosure, preventing contamination from spreading to the workplace.

Q2: Which industries typically use an Emergency Shower and Eyewash Room?

A2: This equipment is widely applied in the petrochemical, pharmaceutical, electronics, food processing, firefighting, and power industries, especially in cleanroom environments requiring strict safety and hygiene standards.

Q3: What are the advantages of choosing a stainless steel enclosure over a traditional model?

A3: SUS304 stainless steel offers high corrosion resistance, durability, and easy cleaning, ensuring long service life and compliance with cleanroom-grade requirements. It is ideal for environments with high safety standards, such as electronic manufacturing and biopharmaceutical production.